Home > News

> News Information

Home > News

> News Information

Metal stamping parts are widely used in various industries, and the dimensional accuracy requirements for metal stamping parts vary for different products. For precision industries such as watches and healthcare, the dimensional accuracy of metal stamping parts is higher. So, what is the difference between precision metal stamping and ordinary metal stamping, and what factors affect it?

What is ordinary metal stamping

Ordinary stamping does not require high precision for stamped parts, and the substrate thickness is relatively thick, without the need for cutting, cutting, stretching, and other processes. Ordinary stamping can meet the requirements. Ordinary stamping processing is generally used for stamping large hardware parts, such as stamping bowls and basins, which can be called ordinary stamping. If it is larger or smaller, it will not affect its rice filling function, and can be called ordinary stamping.

Overall, the difference between precision stamping and ordinary stamping lies in the requirements for stamping equipment and the precision of the required stamped parts. If users require high-precision stamping parts and a large number of stamping parts, they can choose to use precision stamping; Otherwise, if the precision of the stamped part is not high and the stamped part is made of ordinary sheet metal.

What is precision metal stamping

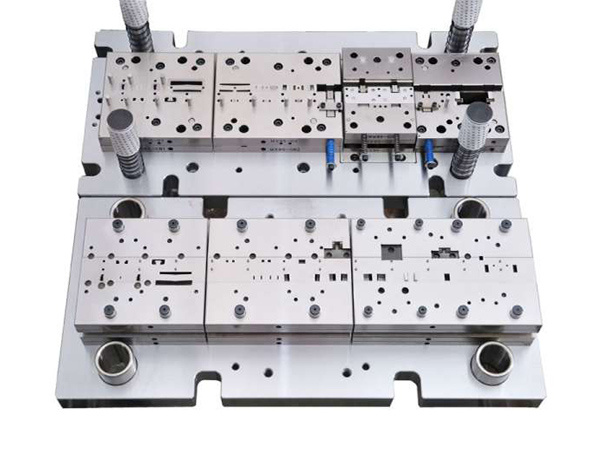

Precision stamping is a material processing method developed on the basis of ordinary stamping technology. It is achieved by improving the guiding accuracy of metal stamping molds, reducing the gap between metal stamping convex and concave molds, and realizing the process of precision stamping or the combination of precision stamping and other forming technologies.

The precision stamping accuracy of stamped parts requires consideration of suitable precision punching machines, molds, materials, lubricants, and other technical supporting requirements during the processing and production of stamping coils or forming. In the production process of high-precision metal stamping, the mold master needs to have good knowledge of stamping mold design, material properties, and material lubrication.

Factors affecting the accuracy of precision metal stamping parts:

1. The punching sequence for precision metal stamping is incorrect.

2. During the precision metal stamping and punching process, the springback causes the shape of the previous process part to be inconsistent with the shape of the supporting surface of the next process mold working part, resulting in deformation of the precision stamping part during the punching process, thereby affecting the dimensional accuracy.

3. Due to poor positioning during operation, precision metal stamping causes the billet to move during the punching process. Or defects in the cutting area (such as angularity, missing edges, etc.) can cause inaccurate positioning, resulting in dimensions exceeding tolerances.

4. The quality of raw materials used for precision metal stamping is very poor.

5. The blade size of precision metal stamping molds exceeds the tolerance range.

6. Due to improper adjustment of the previous process or wear of the rounded corners in the multi process production of precision metal stamping, the principle of equal volume during deformation is disrupted, resulting in dimensional changes after stamping.

7. The shape of precision metal stamping sheet is not good.

.jpg)