Home > News

> News Information

Home > News

> News Information

1、 Reasons for low power in precision metal stamping factories:

(1) Unreasonable production scheduling

Production scheduling has a significant impact on precision metal stamping factories, and arranging production plans reasonably can greatly improve the power of stamping factories. Stamping processing has many production tasks, and there are significant differences between different tasks. How to arrange production plans reasonably, so that the vacancy rate of workshop equipment is low, the switching time of products is short, employees have a high level of understanding of products, and reduce frequent income and expenditure of semi-finished products and waste products.

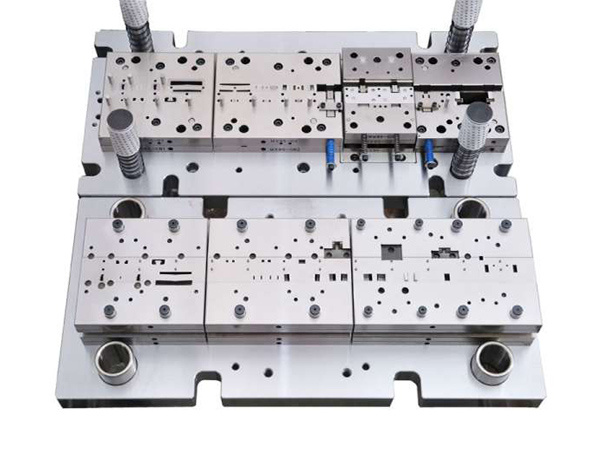

(2) The state of punching machines and stamping molds is unstable

Stamping products have complex structures, and the complexity of punching machines and molds is relatively high. Stamping workers are required to have a certain understanding of the complexity of the product, to do a good job in quality control of the production process, and skilled workers are also required to have appropriate knowledge of the operation and protection of the punching machine and mold to avoid problems and minimize them at all times. Due to poor cutting press and mold conditions, production is slow and affects the project schedule.

(3) Chaotic handling

In the production process of precision metal stamping factories, there are a large number of products and a variety of production types, and there are few means of actively collecting and recording data. The difficulty of calculating and collecting data throughout the entire process is high; In addition, with mixed line production, different standards for stamping parts after conversion have different requirements for different types of production, making it more difficult for employees to handle. Precision metal stamping enterprises often rely on experience, and processing is the gradual accumulation of experience, turning experience into standards that can be promoted.

2、 Methods to increase power in precision metal stamping factories

(1) The production plan for stamping parts in precision metal stamping factories is based on the company's production and operation plan, and must first meet the annual customer demand. Based on the storable characteristics of other stamping parts, the workshop plans its own lower inventory to balance meeting customer needs, minimizing inventory to reduce storage costs, and reducing inventory alarm risks through limited inventory, thereby ensuring the supply time of stamping plant production equipment and molds.

(2) The quality of raw materials must be inspected. The mechanical properties of steel directly affect whether qualified stamping products can be obtained. Stamping enterprises compare the testing data of steel plates with the corresponding conditions of the produced parts, and obtain the functional parameter range of steel that can produce qualified parts. By continuously optimizing stamping molds and expanding the functional range of steel, the goal of cost savings is achieved. In addition, the thickness and viscosity of the oil film on the surface of steel also largely determine its forming function, and cannot be produced when the oil film is abnormal.

(3) Daily protection of punching machines. Precision metal stamping factories should focus on improving the skills of maintenance workers, carry out diversified technical training and competitions for maintenance workers, cultivate the correct thinking and methods of solving problems for maintenance workers, and invent punch protection manuals suitable for this workshop through a large number of fault cases.

(4) Protection of stamping molds. For the maintenance of stamping molds, equal emphasis is placed on improving personnel skills. Because the employees in the stamping workshop are relatively young, with an average age of around 25, improving their skills is particularly important.

.jpg)