Home > News

> News Information

Home > News

> News Information

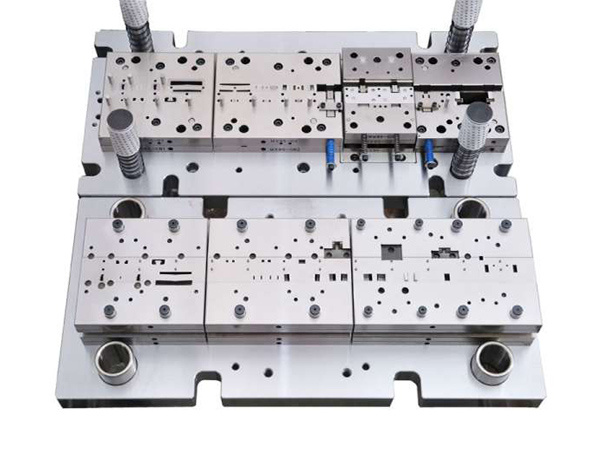

There are three main requirements for precision metal stamping technology in practical industrial applications: quality, appearance, and accuracy. Different products have different focuses, for example, automotive stamping parts focus on quality, electronic products focus on appearance, and financial equipment focuses on precision. Therefore, customers can find their main strengths or selling points based on the field of the product and choose the supplier that suits them.

1. The quality of precision metal stamping technology. Every era has different demand words. In the past, having something meant satisfaction, and there was no unified standard for the concept of quality. Just think about the common people in feudal times who were quite satisfied with owning a new hoe, no matter how long the metal sheet could last. Later on, everyone had hoes, and it was time to compare whose hoes would last longer and have better hardness. The word 'quality' became the industry standard, to the extent that every industry later had quality standards. To improve, it is necessary to first improve the quality of stamped parts, especially in the automotive industry. Attention should be paid to safety performance, which may lead to collisions. The requirements for hardness and plasticity are relatively high, so you will pay close attention to these two points.

2. The appearance of precision metal stamping technology. In fact, it is another extension made under the premise of a unified quality standard - aesthetics. In this era, material wealth is becoming increasingly abundant and material desires are rampant. Consumers are no longer satisfied with the concept of only being able to use it in the past, but also have new pursuits for appearance. Especially, electronic products with fashionable appearance are more popular in the market, and market demand is driving them to improve in surface treatment. Obviously, these changes are made with a demand-oriented approach, in line with market development and consumer needs.

3. The precision of precision metal stamping technology. A very obvious example is financial equipment. It's not that the first two points are not required, but the quality and appearance requirements can only meet common standards. Common examples include note counting machines, which require the thickness tolerance of the metal part of the note export module to be no less than 0.02mm or even smaller. When choosing suppliers, special attention should be paid to the accuracy of the production equipment. Overall, mature precision control equipment is better than punching machines from Germany, Japan, and other countries (technology knows no borders).

.jpg)